What is Ethyl Acetate?

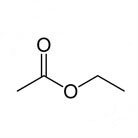

Ethyl acetate (also known as ethyl ethanoate, acetic acid ethyl ester, acetoxyethane, 1-acetoxyethane, EtOAC, ETAC, EA) is an organic ester compound with a molecular formula of C4H8O2. It is a colourless liquid with a fruity characteristic odour that is commonly recognised in glues and nail polish remover. Ethyl acetate is extremely flammable with a flashpoint of -4° C and a flammability rating of 3 and is also highly miscible with all common organic solvents (alcohols, ketones, glycols, esters) but only slightly miscibility in water. This product is commonly used as a solvent for cleaning, paint removal and coatings.

Technical Properties

Chemical and physical properties of ethyl acetate:

Molecular Formula: C4H8O2 / CH3−COO−CH2−CH3 / CH3COOC2H5

Synonyms: ethyl ethanoate, acetic acid ethyl ester, acetoxyethane, 1-acetoxyethane, EtOAC, ETAC, EA

Cas Number: 141-78-6

Molecular Mass: 88.052429 g/mol

Exact Mass: 88.052429 g/mol

Flashpoint: 24°F / -4°C

Boiling Point: 171°F / 77.1 °C at 760 mm Hg

Melting Point: −83.6 °C / −118.5 °F

Vapour Pressure: 93.2 mm Hg at 25 °C

Water Solubility: 64 g/L (at 25 °C)

Density: 0.902 g/cm3

Log P: 0.71

How is ethyl acetate made?

There are various methods for manufacturing ethyl acetate. Originally, it was synthesised by distilling ethanol and acetic acid in the presence of sulfuric acid. It is now primarily produced commercially via the Tishchenko method of condensing two equivalents of acetaldehyde using an alkoxide catalyst.

2 CH3CHO → CH3CO2CH2CH3

Another primary method is using Fischer esterification which involves reacting acetic acid with ethanol, a process accelerated by acid catalysis.

CH3CO2H + CH3CH2OH → CH3CO2CH2CH3 + H2O

Other methods include as a by-product of the oxidation of butane with acetic acid, the ethanolysis of polyvinyl acetate, and the alkylation of acetic acid.

Handling, Storage & Distribution

Hazards & Toxicity

Ethyl ethanoate has an NFPA health rating of 1 and can cause significant irritation. Overexposure to the eyes, nose and skin can cause irritation, drowsiness, and unconsciousness. If inhaled, ethyl ethanoate can irritate the throat and respiratory passages and cause headaches and nausea.

An NFPA fire rating of 3 indicates that it can be ignited under almost all ambient temperature conditions. Heat, sparks, or flames can ignite this solvent and create vapours that will travel to the source of the ignition. These vapours are heavier than air and will, therefore, spread into surrounding areas.

An instability rating of 0 indicates that it is normally stable, even under fire conditions.

Safety & Procedures

Personal protective equipment should be worn at all times when handling ethyl ethanoate. Eye protection must be worn even when contact lenses are being used. If contaminated, hands should be washed immediately, and clothing should be removed and replaced.

In the case of spillage, isolation of leak area of 50 metres in all directions is recommended. All ignition or flame sources should be removed and entryways into water systems and sewers should be prohibited. Soak up and absorb the spillage using combustible materials. Only attempt to eliminate the leak if it is safe to do so.

Responses for firefighting include using dry chemical, CO2, water spray or alcohol-resistant foam extinguishers for smaller fires. Larger fires require fog or alcohol-resistant foam.

Storage & Distribution

A chemical stockist would have a bulk petrochemical storage facility to regulate this product. Storage is normally in a cool, dry and well ventilated facility away from oxidising agents. Ethyl acetate should be kept out of direct sunlight, heat and open flames. Ethyl acetate should be stored in drummed containers such as iso tanks made of stainless steel, aluminium or carbon steel.

A bulk solvent exporter would normally distribute this solvent in bulk vessels or tank trucks. For transportation purposes, ethyl acetate is classed as a flammable liquid with a fire hazard rating of 2. A full bulk chemical distributor would export the solvent throughout regions such as the UK, Europe, Africa and America. This product is a packing group 2.

What is ethyl acetate used for?

Ethyl acetate has many uses in the industrial and commercial industries as both a solvent and a diluent.

Industry Uses

Ethyl acetate is used in various industrial applications such as in paints as a hardener, adhesives, paint and coating additives, degreasing solvents, active agents, processing aids and plasticisers. At a lower purity, it can be used in printing and pharmaceuticals. It is also used in coating formulations for wood furniture, agricultural, construction equipment, mining equipment and marine uses.

Laboratory uses include in mixtures used in column chromatography and extractions.

Commercial Uses

The most common use of ethyl acetate is as an ester in wine as it is naturally produced during the fermentation process. It contributes to wine’s fruity flavours. It also contributes to the decaffeination of coffee beans and tea leaves.

Commercial products containing this solvent include automotive products, cleaning and furnishing care products, paints, coatings, inks and plastics. It is also used in air care products and perfumes, as it evaporates quickly leaving only the scent to remain.

As a high purity solvent, it is used in cleaning electric circuit boards and as a nail polish remover. At a lower purity, it can be used as in perfumes, food, decaffeination of tea/coffee and a carrier solvent for herbicides.