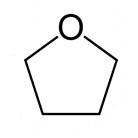

What is Tetrahydrofuran?

Tetrahydrofuran (THF) is a clear, colourless, organic compound with an ether-like odour and the formula (CH2)4O. It is primarily used as a precursor to polymers including for surface coating, adhesives, and printing inks. It is water-miscible and has a low viscosity making it a highly versatile solvent used in a variety of industries.

Technical Properties

Chemical and physical properties of tetrahydrofuran:

Molecular Formula: C4H8O / (CH2)4O / (CH2)3CH2O

Synonyms: THF, oxolane, 1,4-epoxybutane, oxacyclopentane, butylene oxide, cyclo tetramethylene oxide.

Cas Number: 109-99-9

Molecular Weight: 72.11 g/mol

Flashpoint: 6 °F / -14.4 °C

Boiling Point: 151 °F at 760 mm Hg

Melting Point: -163.3 °F / -108.5 °C

Water Solubility: miscible

Density: 0.888 at 68 °F

How is it produced?

Reppe Process

Tetrahydrofuran was traditionally produced using the Furfural process where furfural, extracted from corn husks, is used as the raw material in production. However, the disadvantage of this method is that supply depended on agricultural conditions and could not therefore be relied upon, so a move was made to the fully synthetic Reppe process.

In the Reppe process, ethyne and formaldehyde are used as the raw materials that produce 1,4-butanediol, at the first step. Tetrahydrofuran can then be obtained via the acid-catalyzed dehydration of 1,4-butanediol in the presence of an acidic ion exchange resin. This is currently the main method of extraction employed throughout the world.

A second major industrial method of manufacturing THF is the hydroformylation of allyl alcohol followed by the subsequent hydrogenation to resulting in 1,4-butanediol.

Oxidisation of n-butane

Another method is a two-step butadiene chlorination process that yields 70-75% THF. Developed by DuPont, it involves oxidising n-butane to create maleic anhydride followed by catalytic hydrogenation over a palladium catalyst. It is a relatively simple process and one that is of interest to chemical producers.

Catalytic hydrogenation of furan

Tetrahydrofuran can also be produced, or synthesised, via catalytic hydrogenation of furan. This process involves converting certain sugars into THF by digesting to furfural. An alternative to this method is the catalytic hydrogenation of furan with a nickel catalyst.

Other methods include the decarboxylation of furfural and the oxidisation of butadiene.

The world annual production of tetrahydrofuran is approximately 200,000 tonnes and it is predicted that demand and production will grow as the Chinese economy continues to expand.

Handling, storage and distribution

Hazards and Safety

Tetrahydrofuran has an NFPA health rating of 2, indicating that it can cause temporary incapacitation or residual injury. Inhaling excessive amounts of vapour can cause nausea, headaches and dizziness. Contamination of the skin and eyes can irritate. A flammability rating of 3 indicates that it can be easily ignited under almost all ambient temperature conditions. Vapours will travel to the source of the ignition and flashback. It has an instability rating of 1 indicating it is stable but can become unstable at heightened temperatures.

Full PPE should be worn when handling THF to prohibit contact with the skin and eyes. This includes full protective clothing, including gloves, and eye protection. The skin should be washed immediately if it becomes contaminated and wet clothes should be removed and replaced.

Storage and distribution

Tetrahydrofuran is stored in tightly sealed metal drums and/or amber glass containers. It has a specific gravity of 0.89 and a flashpoint of -17.2° C (closed cup) and is highly flammable. It should be stored in a cool, dry, and well-ventilated area that is free from the risk of ignition. For transportation purposes, tetrahydrofuran is classified as packing group III and hazard class 3 and should be labelled as an irritant.

What is Tetrahydrofuran used for?

Industry Uses

Tetrahydrofuran has many industry uses as a solvent including in natural and synthetic resins, high polymers, fat oils, rubber, polymer and protective coating, adhesives, inks, tetramethyl lead, PVC and in the production of nylon and adipic acid.

It is also used as a reaction medium, primarily in the pharmaceutical industry, in processes such as Grignard syntheses or lithium aluminium hydride reductions. Grignard synthesis examples include butyrolactone and succinic acid. It is also used as a Grignard reagent in the synthesis of synthetic perfumes, pharmaceuticals, motor fuels and insecticides.

Tetrahydrofuran is a valuable chemical intermediate as it is a precursor to polymers, such as poly (tetramethylene ether) glycol. The primary use of this polymer is the production of elastomeric polyurethane fibres like Spandex. It is also an intermediate in the natural gas industry where it is a natural gas odorant.

Other industry uses include in intermediates, processing aids and plasticisers.

Commercial Uses

Commercial uses of Tetrahydrofuran include in adhesives, paints and coatings and solvents.